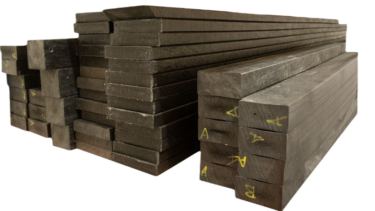

Circular11 – Carbon-negative plastic lumber, directly diverting local waste from incineration.

Circular11 turns plastic waste into carbon-negative composite materials for infrastructure.

Circular11 have developed a machine-learning driven manufacturing process that takes film-based and mixed plastic waste streams, and dynamically adjusts the manufacturing process to create a standardised material that replaces timber, concrete, and steel in non-structural outdoor applications. This technology creates a scalable recycling pathway for the 70% of post-consumer plastics that cannot be recycled because of unavoidable mixtures of co-polymers, additives and polymer grades. It also allows the use of material that recyclers currently have to pay to dispose of, dramatically reducing cost of goods and making durable carbon-negative materials affordable enough for the mass-market.

Circular11 are scaling this up in our own manufacturing operations, producing lumber, fencing, furniture, and light-shelters for national infrastructure providers in the road, rail, and construction sectors. We aim to expand our manufacturing operations across Europe, before joint-venturing with recyclers in emerging markets to expand access to both waste management and sustainable construction materials.

Benefits

- EPD-Verified Carbon Negative Footprint.

- Lasts a minimum of 30 years without treatment, as opposed to an average of 8 years for timber (now that many timber preservatives like Creosote have been banned).

- Will be collected and recycled back into another construction product at the end of it’s life.

- Can incorporate on-site plastic waste (films, flexible plastics, and rigid plastics that would not otherwise be recycled).

- Stronger and stiffer than competitor products in the plastic lumber market.

Get in touch with our Innovation Partner

Simply fill in the form below and we’ll get right back to you.