UPB – All-in-one precast façade panel – Increase construction efficiency, quality, and sustainability by insulated, glazed architectural façade panel

Increase construction efficiency, quality, and sustainability by insulated, glazed architectural façade panel.

External facade envelope traditionally requires a combination of several labour-intensive trades like brick-layers, glazing and internal works. This results in complex procurement, site management and sign-off. Nevertheless, scaffolding adds not only extra costs, but also additional health & safety risks as large site teams work at heights.

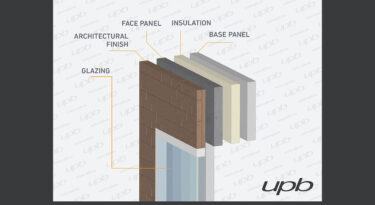

UPB’s structural 3-layer precast panel ensures a complete wall build-up that is achieved in a factory-controlled setting with minimal on-site work & labour. The all-in-one precast panel provides architectural finish, installation, fully framed & flashed glazing with interior finish ready for paint. Panel also serves as a loadbearing external wall reducing the need for perimeter columns ensuring better net lettable area and more freedom for interior planning.

UPB’s precast solutions are manufactured in one of the most recent precast facilities in continental Europe with high sustainability credentials, i.e., using only renewable energy for operations. Also, UPB unitised curtain wall and glazing factory is just 1 mile away and located next to a major harbour ensuring swift deliveries to key developers and main contractors across various geographies.

Benefits

- Cost effective

- Carbon savin

- Manufactured in controlled environment

- Faster assembly process

- Reduced maintenance

- Increased lifespan for the structure

- Reduced complexity and element weight

- Material savings on superstructure and foundation

- Waste reduction

- Reduced transportation costs and co2 emissions

DOWNLOAD

Further information

Get in touch with our Innovation Partner

Simply fill in the form below and we’ll get right back to you.